The Penny Press

Initial Design

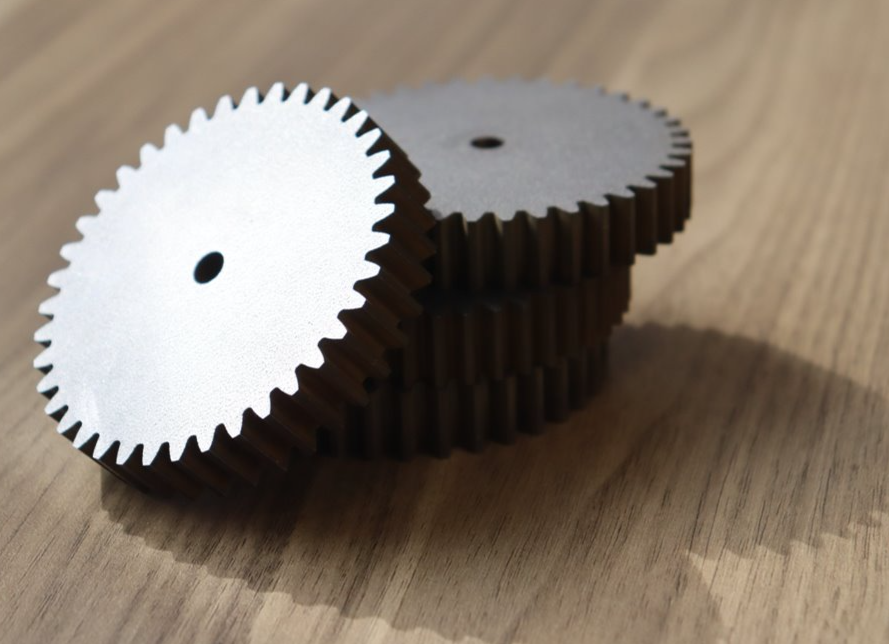

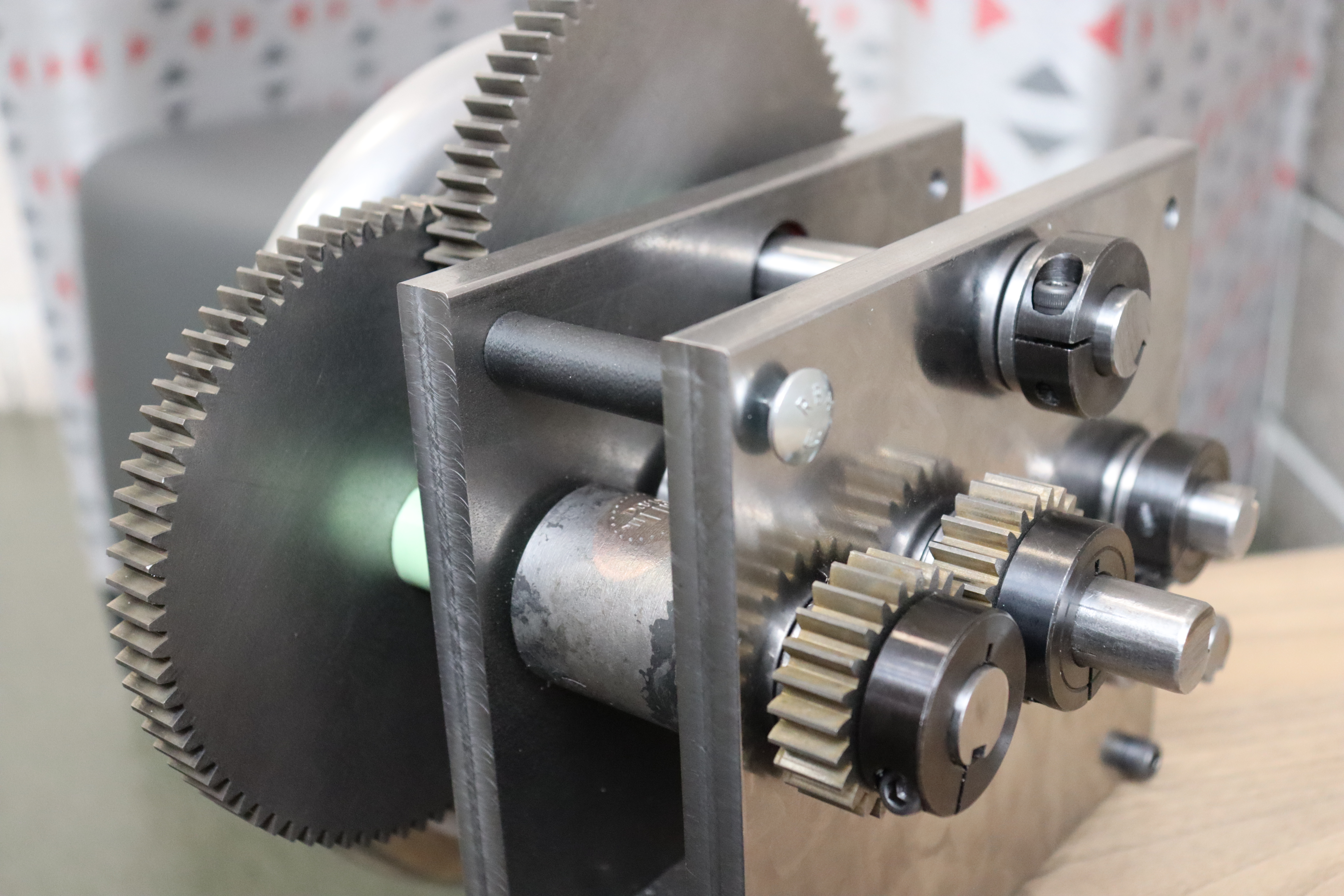

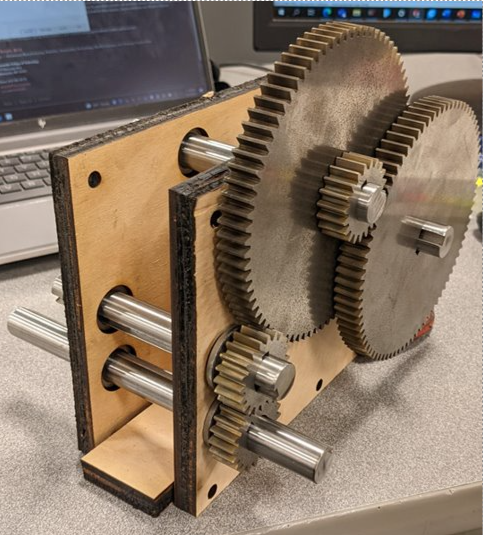

The Penny Press started out with a lot of background research. Roller mill calculations, gear ratios, and strength of materials all greatly impacted the design and manufacturing of the project. We reached out to Stuart Anderson, a robotics engineer who had previously built a penny press as an art installation, and he was able to give some pointers for machining the roller dies and the best gear ratios. From there gears were set up with the correct ratios and placement in a SolidWorks assembly, and side plates were built around the gears. The gears were wire EDM cut, and the plates were laser cut to test placement then manually machined. (New plates were later CNC machined for greater accuracy and better finish)

Rollers

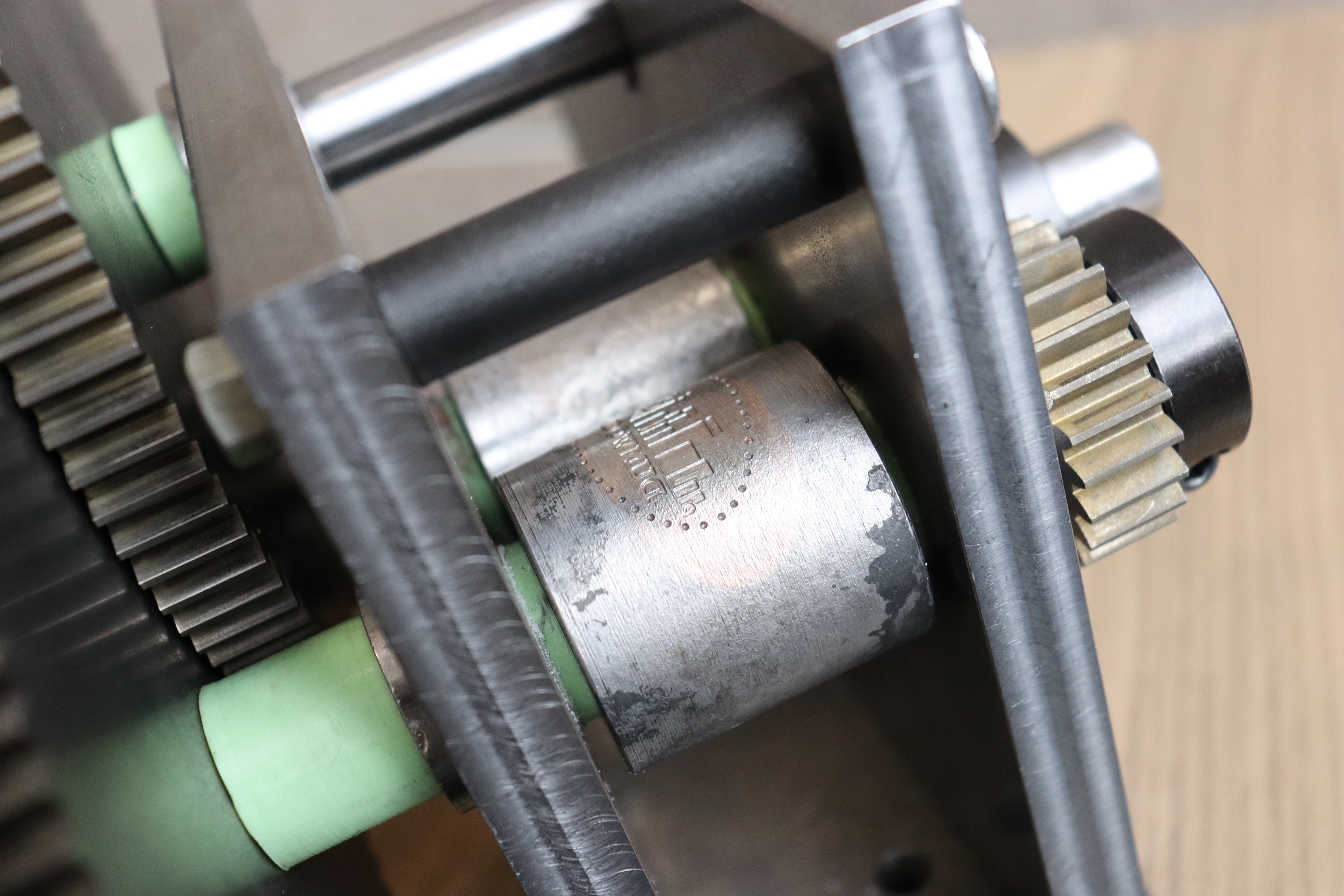

The rollers for the Penny Press were one of the most complex parts due to the wrapping of our design on a cylindrical surface. Due to the geometry, this pattern couldn’t be wrapped onto the cylinder using the wrap tool in SolidWorks, so a series of surface offsets and thickens was used to create multiple bodies the desired depth of the pattern, then a combine- subtract was used to create the cuts. To achieve this geometry for the physical assembly, the rollers were machined using a 4 axis CNC mill setup. The rollers were then heating and rolled in kasenit, heated again and then quenched in order to achieve the hardness necessary to imprint the design without sustaining damage.

Rollers

Final Assembly

The press was assembled with key shafts to lock gears and rollers in place, and oil loaded bearings to reduce friction. The press was then mounted onto a base and covered with a laser cut acrylic housing to properly cover any moving components.

Final Assembly